We make critical components for

industrial equipment utilizing

stainless steel and copper alloys,

with a focus on 3D impellers

that greatly impact the quality of pumps.

We are one of the top producers

in our industry adhering to the

highest standards in quality.

YANAGIMOTO is known for its 3D impellers. We provide more than 20,000 3D impellers annually in different forms and sizes to Japan’s major pump makers.

We own a double-column multitasking machine with 1,600mm max. machining diameter and 1,250mm max. machining length (height), which enables us to process large diameter products using strong lathe turning and milling capabilities.

We have a high quality start-to-finish production with machine processing facilities and engineering skills. It allows us to gain a processing accuracy grind within 0.005mm.

By utilizing 3D scanners and 3D printers, we have been working on making molds digitally. With a 0.28mm lamination pitch in the printer, it makes smooth moldings.

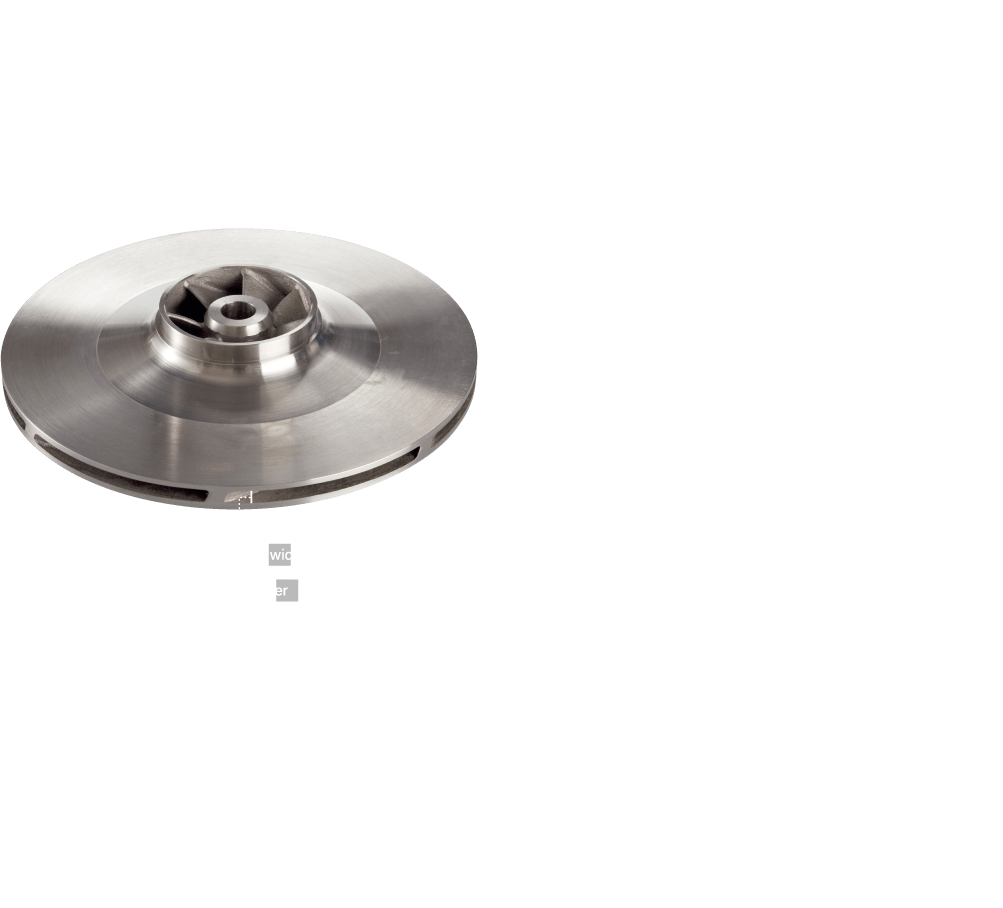

Our special technique to make exquisite cores lets us create 3D impellers with just 2.5mm water channel widths.

While 0.08 - 0.1 for the water channel width ÷ outer diameter is commonly done in sand casting, we have achieved 0.012.

This is the melting temperature in our high-frequency electric furnace. To make our thin impellers we melt our products at a higher temperature than general stainless products.

The amount we can cast in one casting with our high-frequency electric furnace.

3 in Osaka and 1 in Chiba. Using the strength of our start-to-finish production, about 80 employees work hard to always put our customers first while continuing to improve our skills.

7 days after the order is our fastest delivery record for 3D impellers. Working together in close coordination from upstream operation to the final testing enables us to do so.

Yoshiharu Yanagimoto founded the Yanagimoto alloy casting company in Sakai city, Osaka and began producing pump components with copper alloy casting and aluminum alloy casting. We have been growing ever since, continuing to strengthen our start-to-finish production system for casting products.

Our average age (as of 2023). We put an effort into recruiting young people and ensuring that skilled employees pass down the essential knowledge and technical skills so the next generation can thrive.

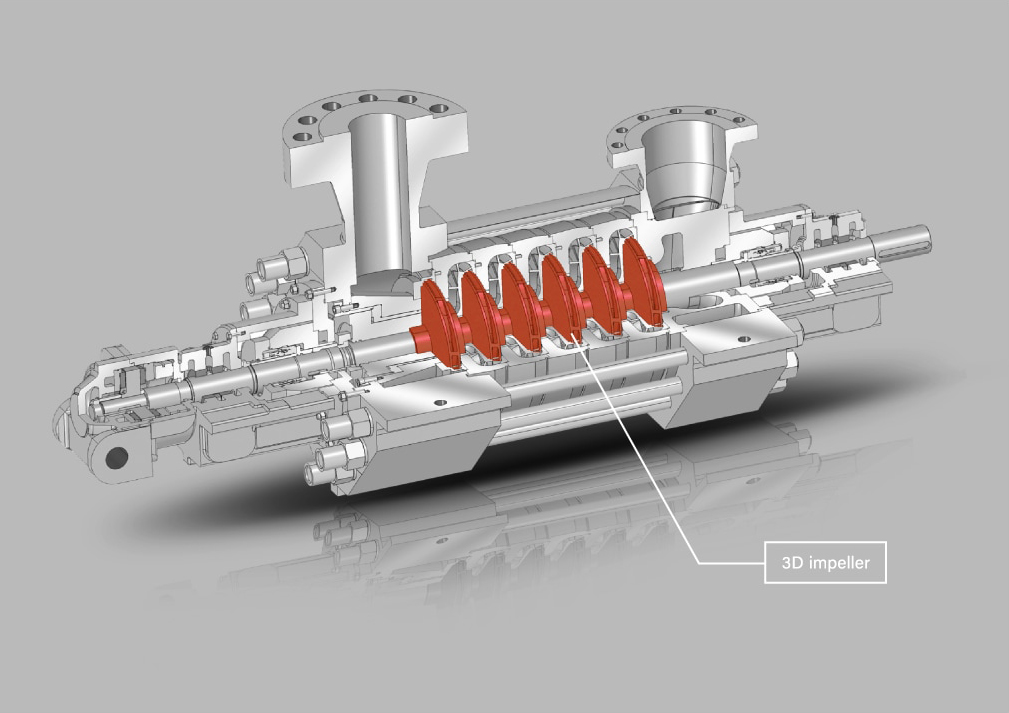

in pumps

The impeller is a crucial component

that rotates inside of a pump to

circulate fluids.

A pump is a device that sends fluid from a lower place to a higher place. When a “3D impeller”

fixed to the main shaft in a pump casing spins, it creates a centrifugal force that acts on the fluid

forcing it to move in the desired direction.

*Picture provided by: Torishima Pump Mfg.Co.,Ltd.

We manufacture impellers with

differing designs depending on the

use case such as open,

closed, double, and many more.

Impeller250CAC402

Impeller250SCS13

Impeller250SCS14

Impeller550SCS1T1

Double Impeller700ASTM6A

Double Impeller400CAC402

Double Impeller600CAC402

Double Impeller300CAC402

Double Impeller700CD4MCU-N

Guide vane420CAC402

Open Impeller300ASTM4A

Open Impeller500CAC402

We manufacture runners

(Francis turbines) used in

small hydraulic power generators.

Runner500SCS13

We manufacture a range of

foundry products with high precision.

LabyrinthCAC402

Valve partsSCS16A

lantern ringCAC402

GlandSCS14